Buttonfly button machines have been produced since 1980. With a 40-year history of production and continuous improvement of this process, we can definitely say that our button badge machine has reached the highest level of quality and durability.

The aluminum frame and steel dies provide a solid and precise construction. Thanks to the rotating base with dies, badges can be produced quickly and efficiently at a rate of 200-300 pieces per hour. The materials used in the production of our machines, as well as the fact that they are manufactured in the EU, ensure their almost unlimited lifespan, and they can produce millions of badges – we have tested it!

We know that our button machine is reliable equipment, and as proof of this, we provide a

LIFETIME WARRANTY

Buttonfly button machines are available for sale in two models:

1. Button machine KDI

- Available sizes: 25mm, 32mm, 38mm, 50mm, 59mm, 75mm

- And rectangular button machine: 68mm x 44mm

- Compact and very stable – for a lifetime 🙂

- Very easy to us

- No interchangeable dies, which means that there is a separate machine for each badge size (this is an advantage – read below why)

If you plan to produce on a larger scale and value the convenience of work, we suggest purchasing this model. The lack of interchangeable parts makes it better suited for frequent use, and having several separate devices for different sizes allows you to make badges of various diameters simultaneously without the need to change dies.

Machine sets with components at a more favorable price:

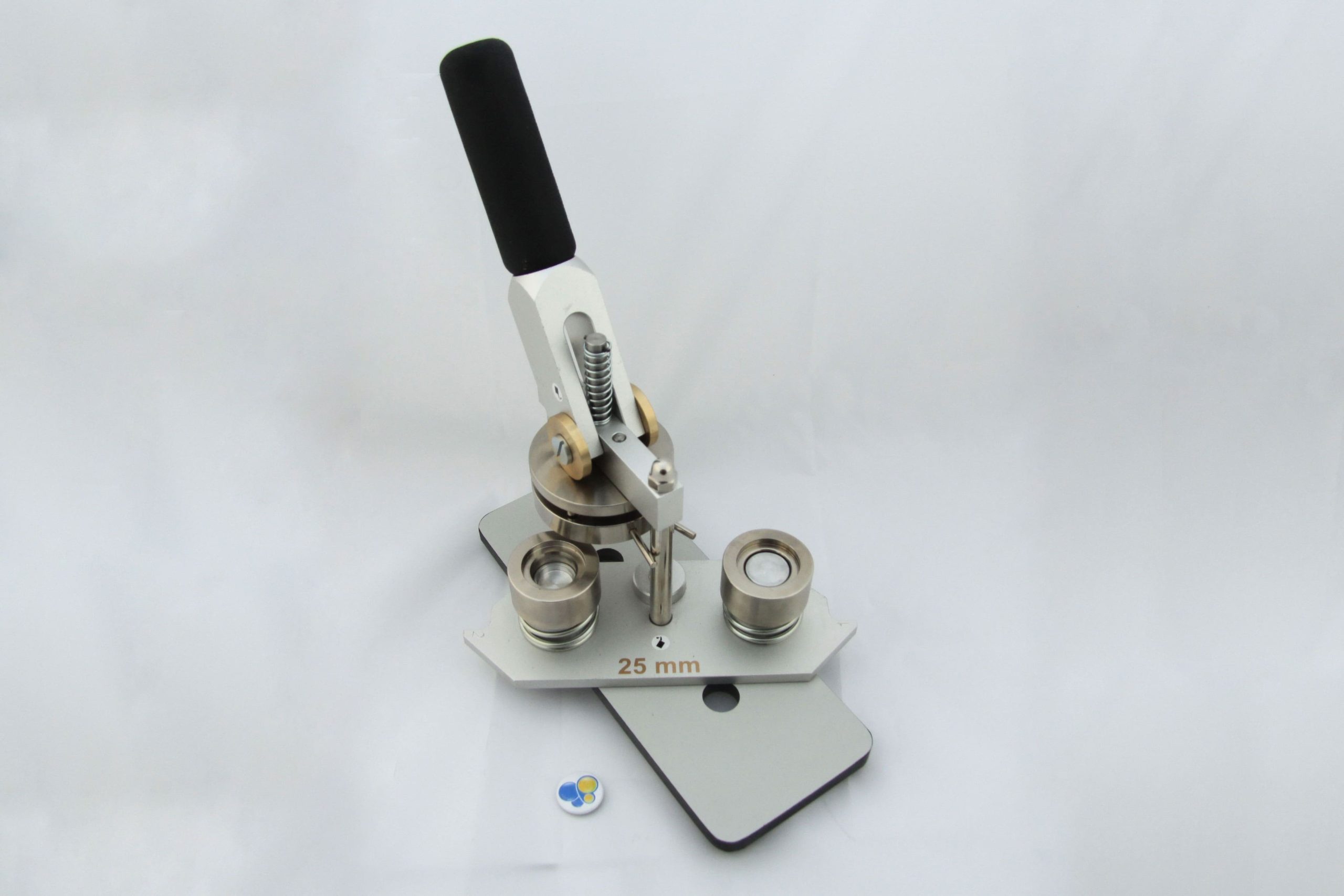

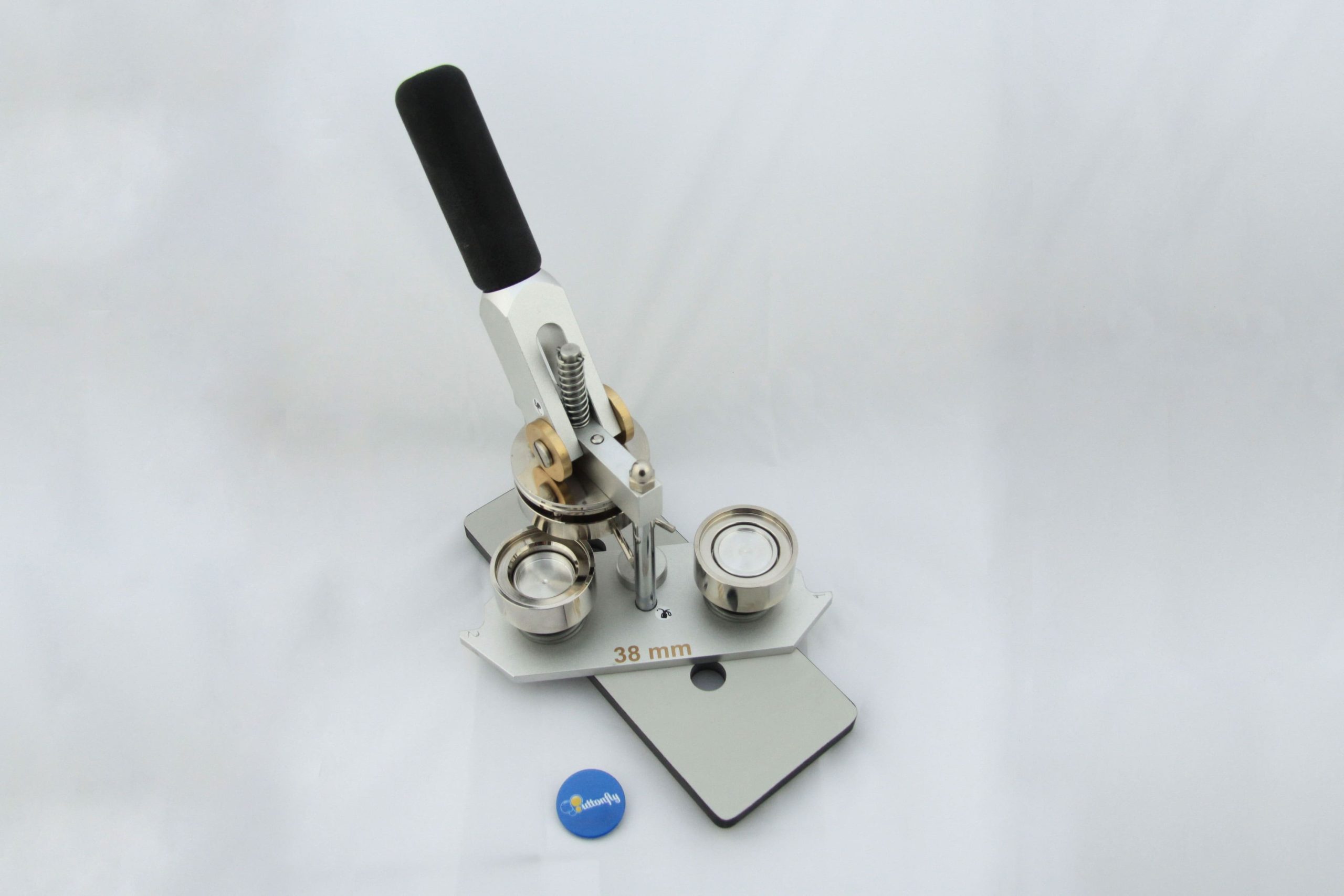

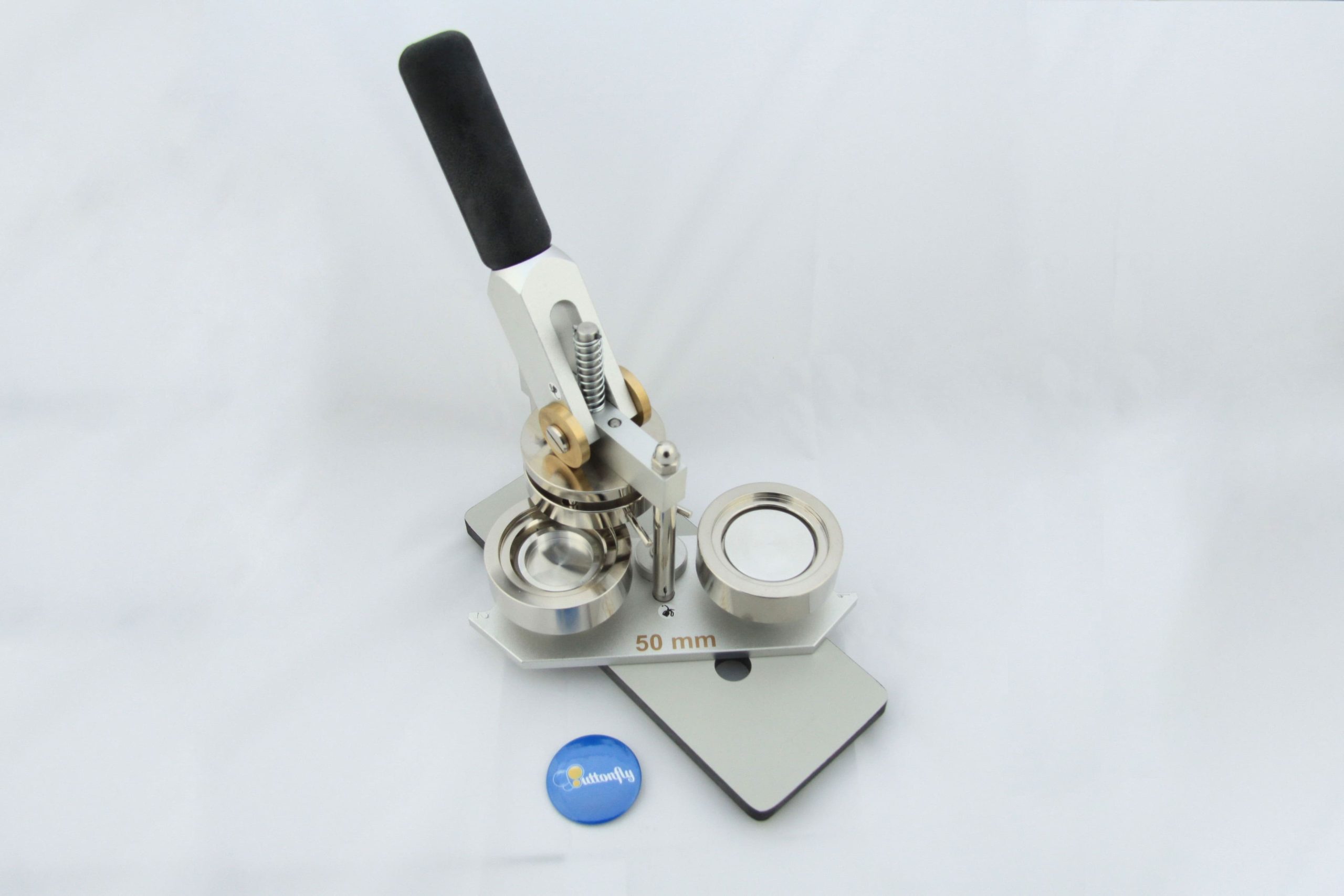

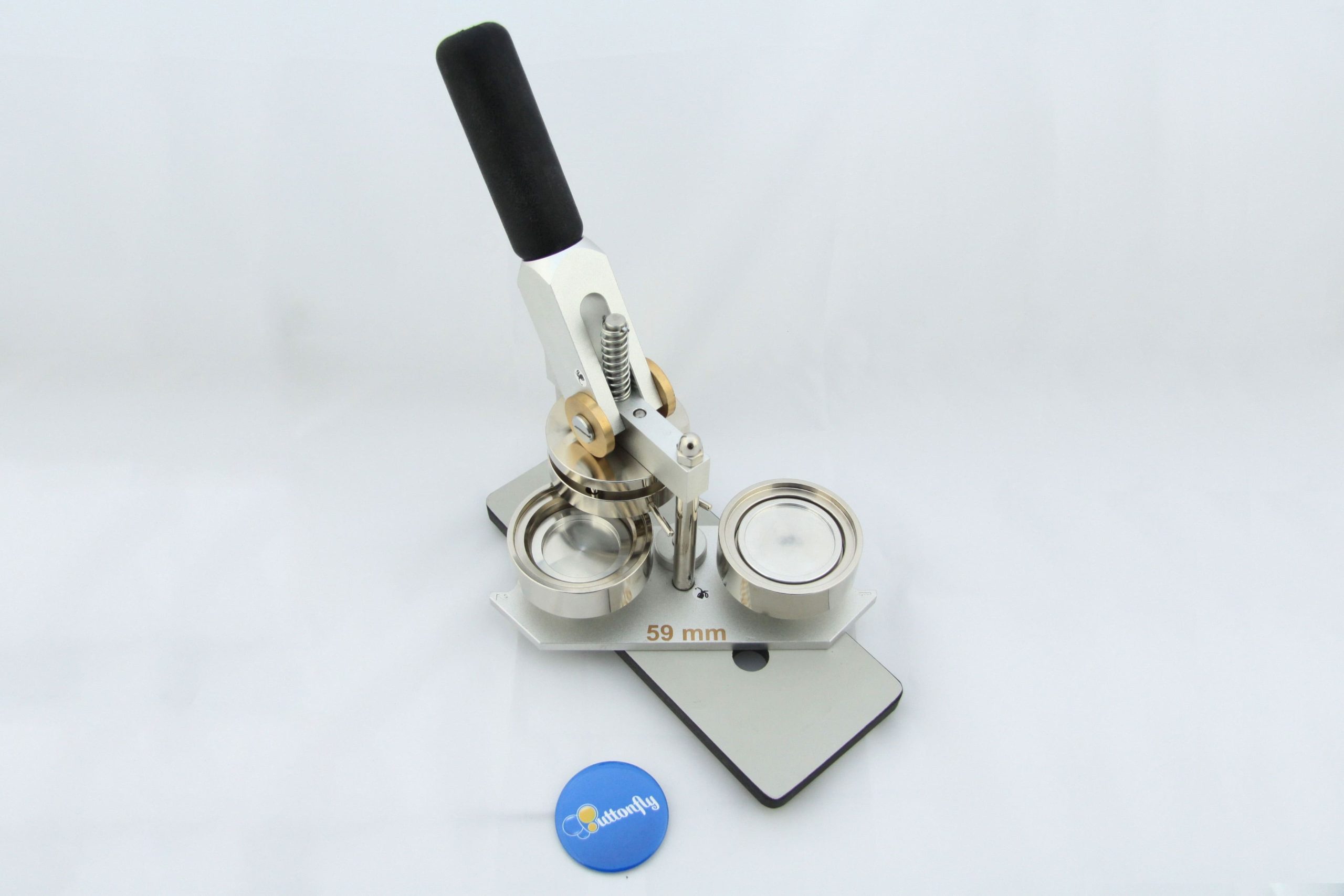

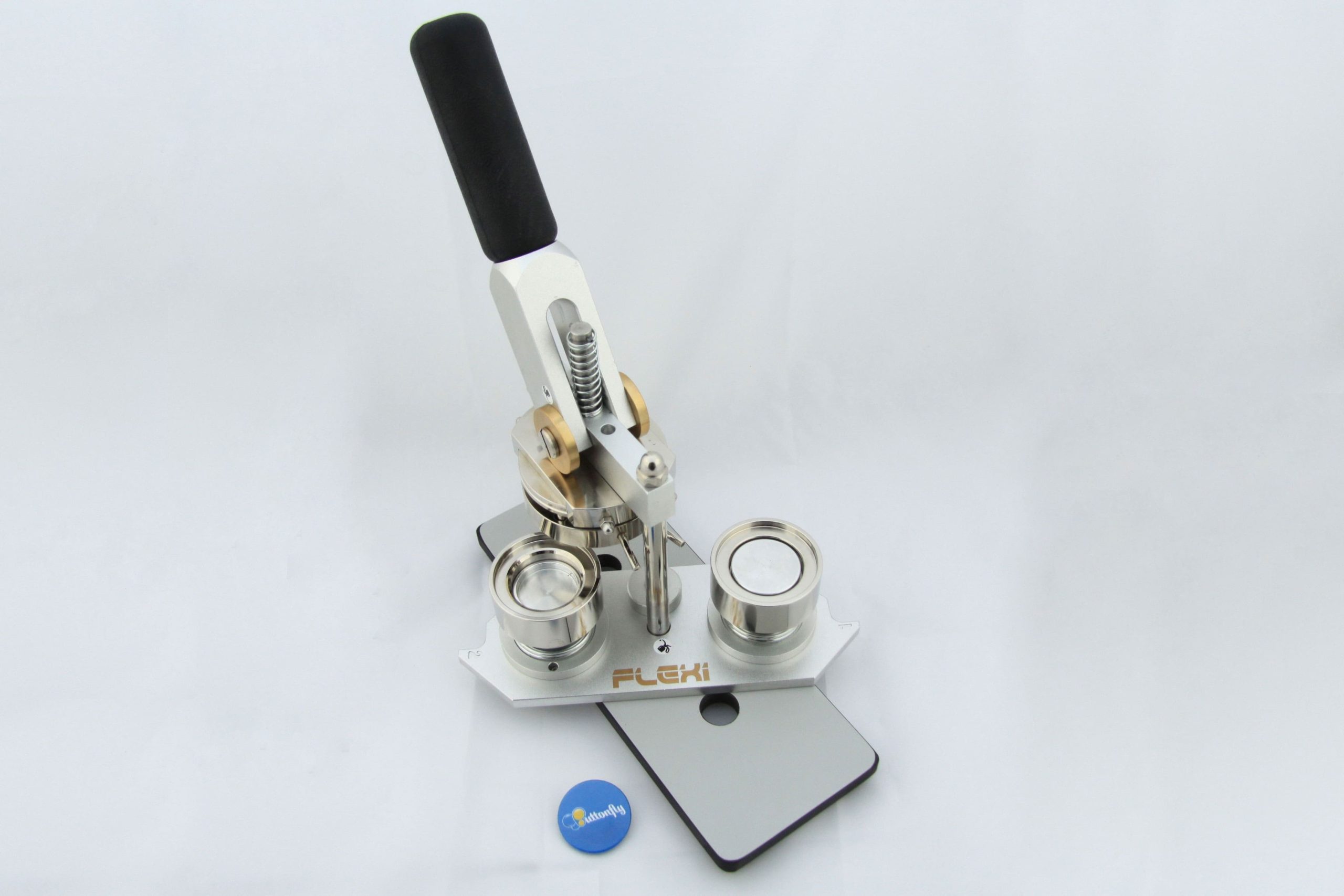

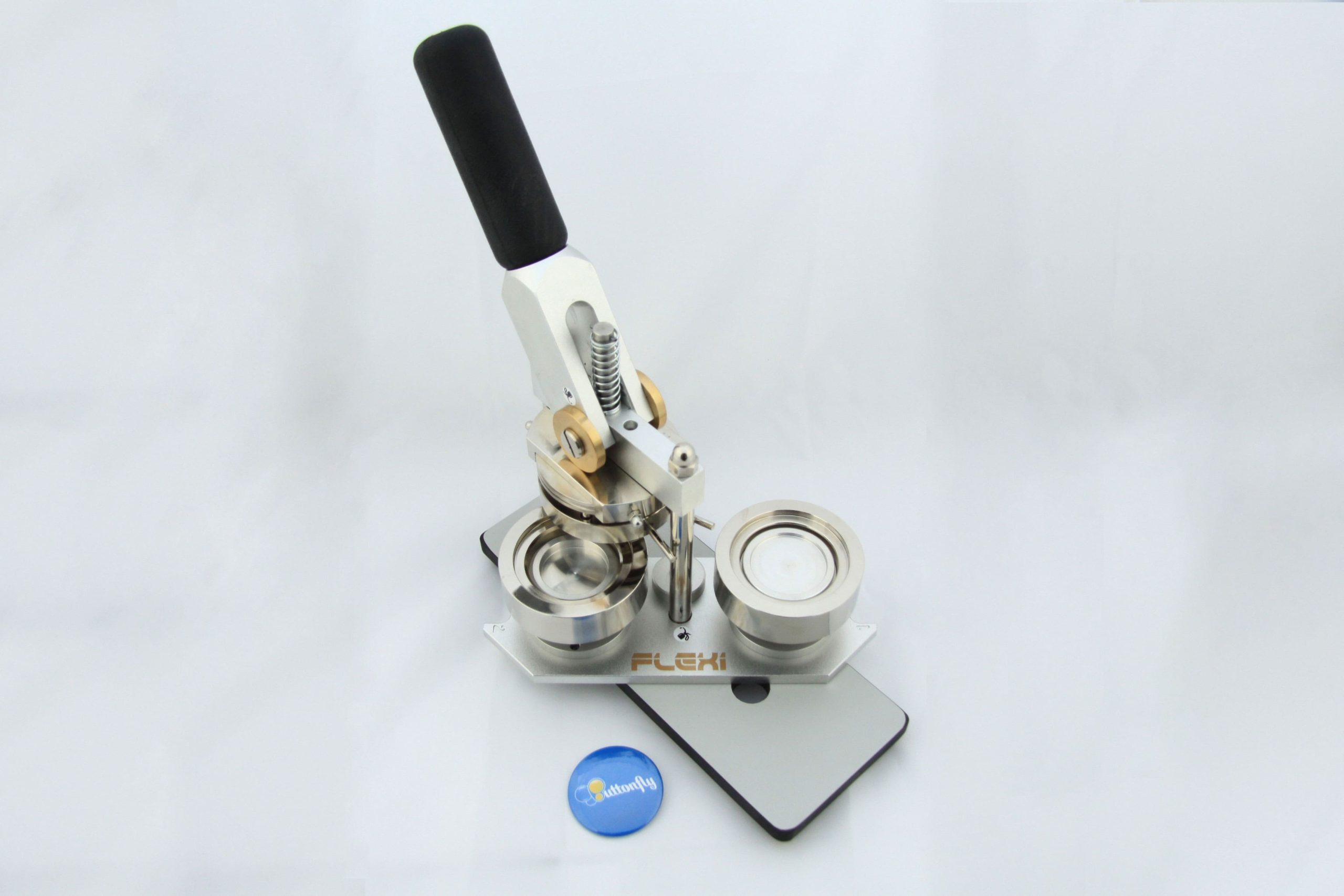

2. Button machine FLEXI

- Available sizes: 25mm, 38mm, 50mm, 59mm

- Interchangeable dies for different badge diameters

- Quick and trouble-free change of badge sizes

- A cheaper solution for two or more sizes

The Flexi machine, as the name suggests, is flexible and adapts to different badge diameters. Initially, the machine is adapted to one selected size with the option to purchase additional dies. Even with two diameters, the price is lower than for two KDI machines. Therefore, it is a great solution when we want to produce different badges in one place. The die exchange is very quick, and at the same time, the device is very stable and precise in production.

Machine sets with components at a more favorable price:

Making badges on our press is very easy.

Badge making press – KDI or FLEXI

Buttonfly offers two generally available models of badge making machines. These are the KDI button machine, available in 6 sizes, and the Flexi button machine, which can be adjusted to 4 different sizes of badges by purchasing additional interchangeable dies in other sizes. How many different sizes of badges you want to make and whether you want to make them simultaneously or not will affect which option will be the better solution for you. The following text should illustrate this well for you.

KDI button badge machine

The KDI button machine is a device for producing one selected size of badges from the available sizes: 25, 38, 50, 59, 75, and 68×44 mm. The advantage of this model of badge press is its compact design and exceptional ease of use. After taking the machine out of the box, simply attach the rubber handle, and you’re ready to make badges. For example, if you purchased a KDI badge making machine for the 59mm size, you can use it to make various types of badges of that size: badges with safety pins, magnets, bottle openers, and even badges with mirrors. Special components for making badges are available for each type of badge, which you can purchase from us.

Flexi button badge machine

If you want to produce badges in different sizes, you have two options – either buy several separate KDI button machines or opt for the Flexi button machine, which has interchangeable dies. With one device, you can produce up to four different sizes of badges: 25, 38, 50, and 59mm. Simply purchase additional dies for the remaining button sizes. Therefore, you have a machine frame to which you attach the selected set of dies, and you’re ready to start producing badges of the chosen size. If you want to produce badges of different sizes, the Flexi model will be a slightly cheaper option and will take up less space. However, remember that you are buying one machine frame and interchangeable dies, so you can only make badges of one size at a time. If you want to have the ability to produce badges of different sizes simultaneously, it is better to invest in separate KDI button badge machines.

Button presses in original sizes

It’s also worth mentioning that among the KDI machines, we also have two original sizes: 75mm, which is a press for making really large badges, and 68x44mm, which is a machine for making rectangular badges. If you like large badges and want to stand out, go for these badge making machines. Because these two machine sizes are much larger than the others, their price is correspondingly higher than for presses for smaller badges.

How to make a button badge on a Buttonfly machine?

Are you wondering how to make a button badge on our machine? On our website, you will find instructional videos – badge production on Buttonfly machines. Our badge-making equipment is very precise, which makes production really fast. Of course, we need to gain some practice because working on badge making machines is manual, but after making the first hundred badges, we should be able to produce around 200 badges per hour. The production of buttons is definitely facilitated and accelerated by a paper cutter because to make a badge, you need components, which you can purchase from us, and a printout that needs to be cut to fit the badge diameter. We offer three models of paper cutters in our offer, which are immediately tailored to the selected badge diameter. Making one button takes a few seconds. How to make a badge? First, place the metal blank, i.e., the badge face, in the machine, then place the cutout print, and finally the acrylic foil, which you receive in the purchased badge component kit. Then, insert the badge component, such as the badge back with a safety pin, magnet, opener, or other type of badge, into the second die. Press the lever of the badge-making machine twice, and you’re done – your first badge is made.

Badge making machine with lifetime warranty

All Buttonfly badge making machines come with a lifetime warranty! You can be sure that you are buying the highest quality badge-making equipment. The components of our badge presses are incredibly durable, and the materials used in their production are top-quality stainless steel and aluminum. The handle of the machine and the feet are covered with rubber for better grip. If necessary, you can unscrew the rubber feet and, using the holes in the base that the badge press has, attach the device to the work table. This makes making badges even faster because you have both hands free.

Kit for making button badges

With the badge-making machine, you will receive an instruction manual and special technical oil. You can see that there are several points on the machine marked with a special sticker where you need to apply a drop of this oil from time to time, let’s say once every 2-3 thousand made badges. A well-oiled machine, which is stored in a box to prevent dust, will last for years, and you can make hundreds of thousands of badges on it – we know something about it! However, if any problems arise with your Buttonfly badge press that you cannot handle, simply return the device to us, and we will perform the necessary service under the lifetime warranty.

You can buy a kit for making button badges in any size at Buttonfly.pl. We have included a discount in the kit prices. Each badge-making kit consists of a selected badge press (KDI or Flexi) and a specified number of the most popular badge components, which are safety-pin components. In the sets with the machine, we offer 100 or 500 pieces of these components.